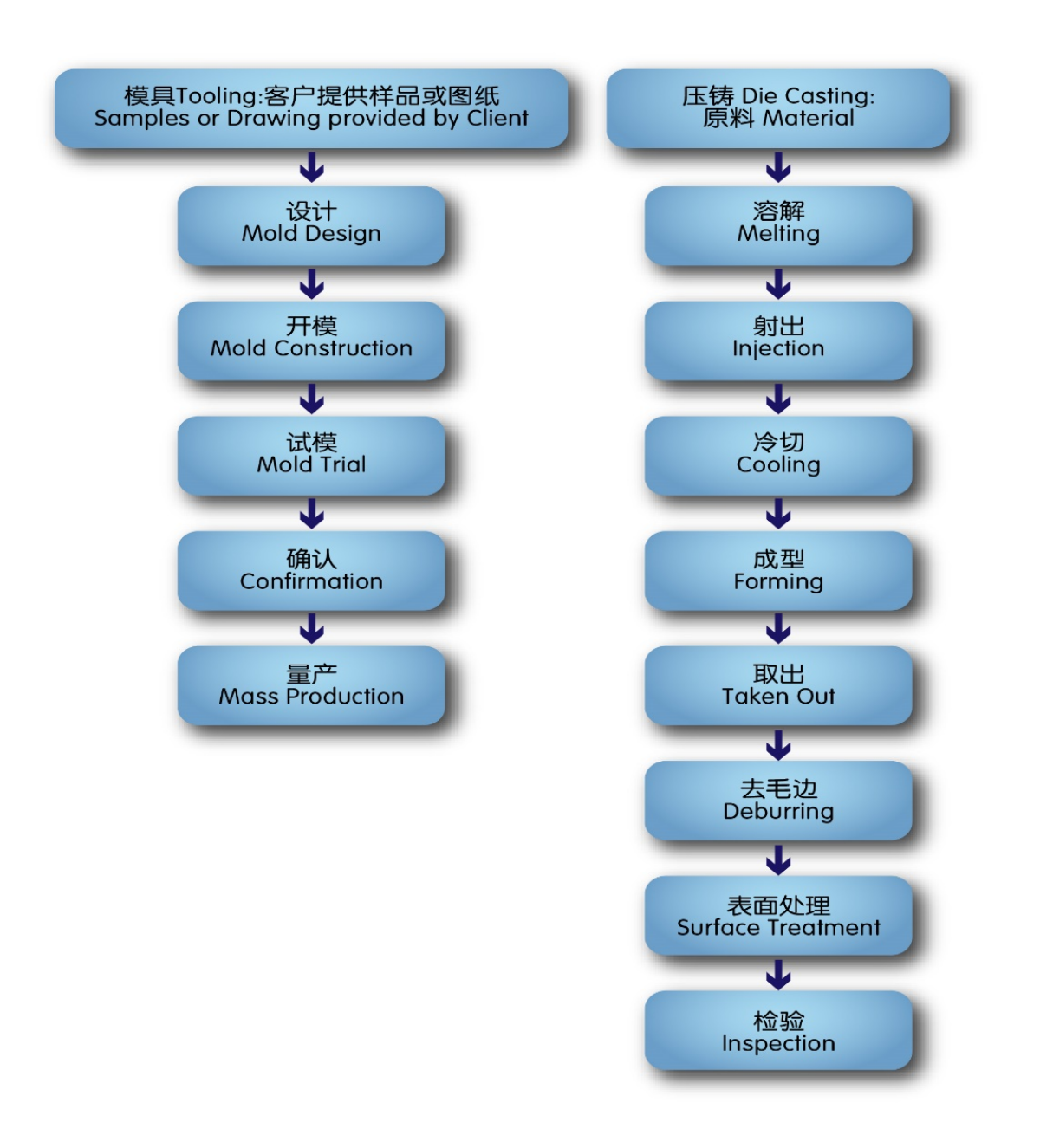

Kutentha kwapadera kwa Die-cast kwa Radiator

Njira yoyeretsera kutentha

Kapangidwe ka zida

Kuthamanga kufa kuponyera

Kudula

Kuchotsa ziphuphu

Kuphulika kwa mchenga

Kupukuta pamwamba

Kuphimba ufa

Kugogoda ndi kupangira makina a CNC

Choyika chozungulira

Chithandizo cha Pamwamba

1. Kusungunuka kwa mankhwala

2. Kujambula

3. Kuyeretsa kwa Electrophoresis

4. Kupaka mafuta

5. Kuphimba ufa

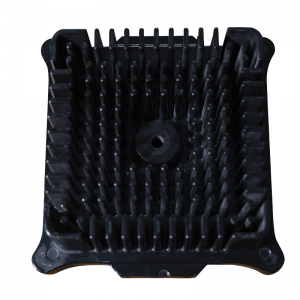

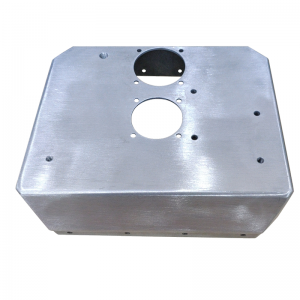

Ma sinki otentha opangidwa ndi die cast

Ma sinki otenthetsera a Die cast ndi abwino kwambiri ngati mukufuna sinki yotenthetsera ya aluminiyamu yopangidwa mwapadera. Amapangidwa poika aluminiyamu yamadzimadzi pansi pa mphamvu yayikulu mu ziwiya zachitsulo. Sinki yotenthetsera ya Die casting ndi yotchuka pamsika chifukwa idapangidwa ndi aluminiyamu. Ichi ndi chinthu chomwe chimakonda kwambiri pa sinki yotenthetsera ya Die casting. Njira zotenthetsera izi ndizoyenera kukwaniritsa zofunikira zonse za polojekiti ndipo zimapanga mwachangu.

Nthawi yotsogolera mwachangu ndi masiku 35-40 okha

Kuchita Bwino Kwambiri pa zomaliza za anodized pamwamba

Miyeso yolimba kwambiri yolamulidwa mkati mwa +/- 0.05mm

Mainjiniya amathandiza kumaliza kuyambira pakupanga mpaka kupanga

Ubwino wa Die Cast Heat Sinks

Poyerekeza ndi njira zina zopangira, kuponyera die kumapereka zabwino zotsatirazi:

1. Pangani mawonekedwe ovuta a 3D omwe sangatheke potulutsa kapena kupanga

chotenthetsera cha aluminiyamu, chimango, nyumba, malo obisika ndi zinthu zomangira zitha kuphatikizidwa mu choponyera chimodzi

2.Mabowo amatha kuyikidwa mu die casting

3. Mtengo wapamwamba wopanga komanso mtengo wotsika

4. Kulekerera kolimba

5. Yokhazikika m'magawo

6. Sikofunikira kukonza makina ena

Perekani malo osalala kwambiri (abwino kuti chitofu chigwirizane ndi gwero lake)

Kukana dzimbiri kuyambira pa zabwino mpaka zapamwamba

Kuyenda kwa njira ya Kingrun

Poyerekeza ndi njira zina zopangira, kuponyera die kumapereka zabwino zotsatirazi:

1. Pangani mawonekedwe ovuta a 3D omwe sangatheke potulutsa kapena kupanga

Sinki yotenthetsera, chimango, nyumba, malo ozungulira ndi zinthu zomangira zitha kuphatikizidwa mu choponyera chimodzi

2.Mabowo amatha kuyikidwa mu die casting

3. Mtengo wapamwamba wopanga komanso mtengo wotsika

4. Kulekerera kolimba

5. Yokhazikika m'magawo

6. Sikofunikira kukonza makina ena

Perekani malo osalala kwambiri (abwino kuti chitofu chigwirizane ndi gwero lake)

Kukana dzimbiri kuyambira pa zabwino mpaka zapamwamba

Chitetezo chabwino kwambiri cha EMI ndi RFI